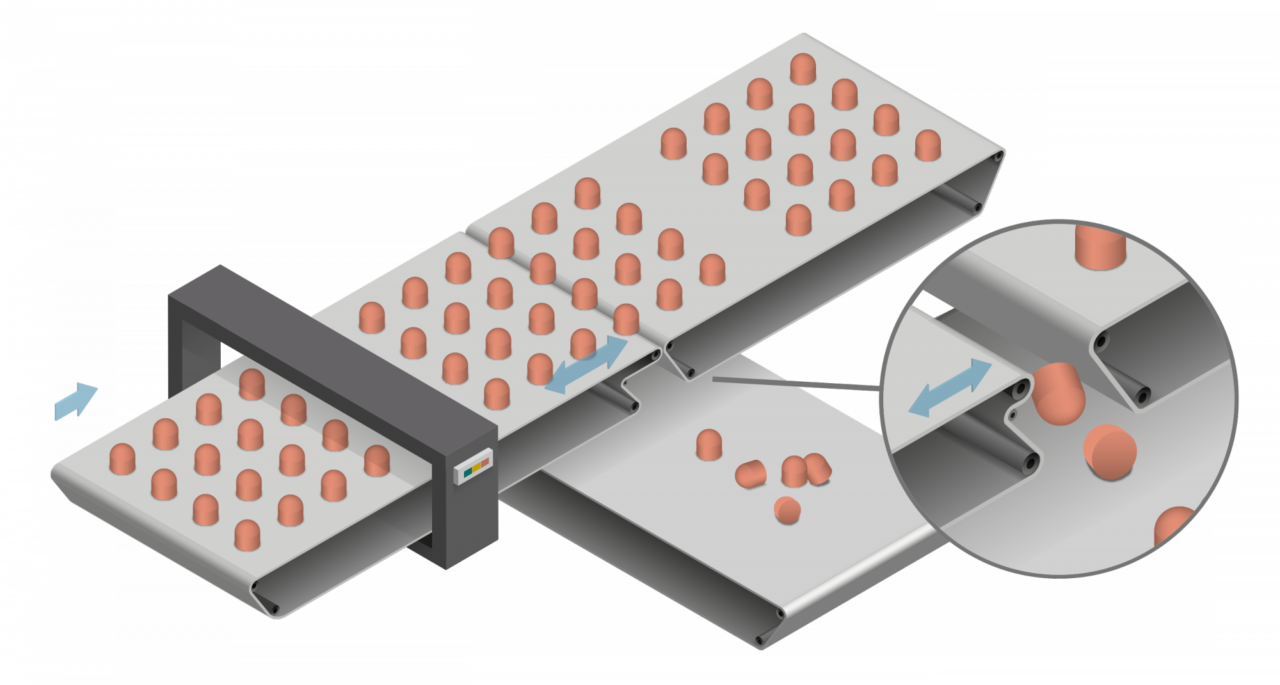

- Integrated cross reject conveyor for the reject of contaminated products to one side and non-properly aligned products for wrapping to the other side

- Optional row aligner for alignment of the products at right angles to direction of product flow

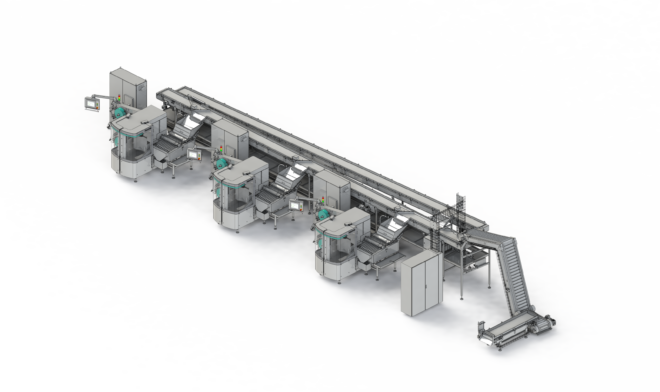

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

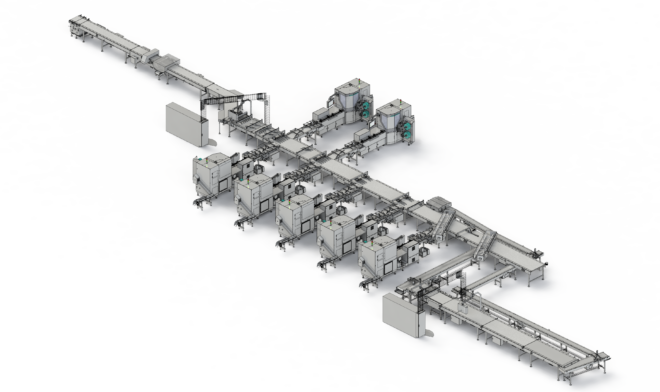

Metal Detector

Detection and rejection of metal contaminated product rows