Flow Pack Machine FPC5: flexible, modular, high-performance

Each of the two packaging lines consists of an FPC5 for primary packaging, which is designed to process five different product formats. Both lines are directly linked to the moulding plant, and each has a downstream cartoner for secondary packaging. Both lines also offer the option of diverting small formats via a return flap. These formats are diverted into collection boxes and transported manually to vertical flow-wrapping machines, where they are packaged into multipacks as bulk goods. The second line which, unlike line 1, can handle not only primary but also secondary packaging if required, includes an additional FPC5, which was specially developed for processing triple multipacks using flow-wrap packaging. To this end, a transfer wheel was integrated to transfer the packaged chocolate bars from the first FPC5 to the second. Once the multipack has been formed, it is also fed directly into the cartoner.

© Theegarten-Pactec GmbH & Co. KG

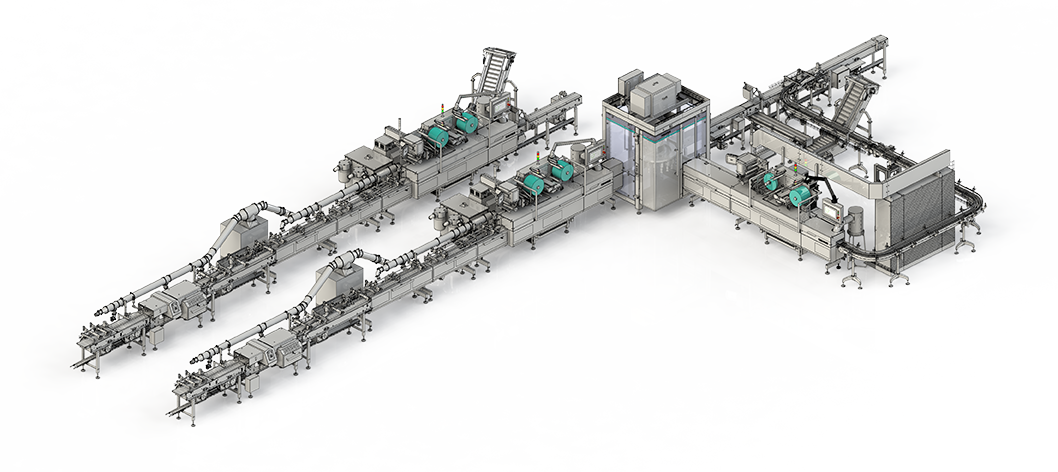

Extremely versatile solution – a complete system consisting of three FPC5 machines spread across two packaging lines, enabling exceptionally flexible production

Three applications, one solution – for maximum production diversity

Three main application scenarios were decisive in the design of the FPC5 to meet the chocolate manufacturer’s specific requirements. The Theegarten-Pactec machine demonstrates its outstanding performance and high flexibility in all three areas of application.

Multi-Format Solution

To achieve the exceptional flexibility of this unique and easy-to-use multi-format solution, Theegarten-Pactec opted for a combination of manual counter adjustment with target value specification. The required settings for each product format – such as the width and height of the belt guides, the position of the print mark sensor and the sealing unit – are stored as product recipes in the touch panel. When changing formats, the operator loads the desired format via the display. The new setpoints are then activated on the respective spindles. These initially switch to ‘red’ because the actual values still correspond to the previous format. The operator then manually adjusts each spindle to the displayed setpoint. As soon as this is reached, the spindle switches back to ‘green’. This visual feedback helps the operator carry out the changeover completely and correctly without the need for manual re-measurement. The deliberately chosen manual solution is not only more economical than fully automatic adjustment via motors, but also much more robust and requires less maintenance, which is especially advantageous given the frequent cleaning intervals required for format changes.

Secondary packaging in flow packs

Another technical highlight is the integrated transfer wheel to the collective packaging machine, which can be operated in active or standby mode as required. This allows individual and collective packaging to be combined efficiently without interrupting the production flow. Moreover, air cooling of the feed belts has been incorporated to ideally protect the temperature-sensitive chocolate. This minimises product adhesion and significantly reduces the cleaning effort in daily production.

With this customised solution, Theegarten-Pactec has once again proven its expertise in challenging packaging processes. Technically advanced, modularly scalable and economical to operate, the machines meet all the requirements of high-tech chocolate production.