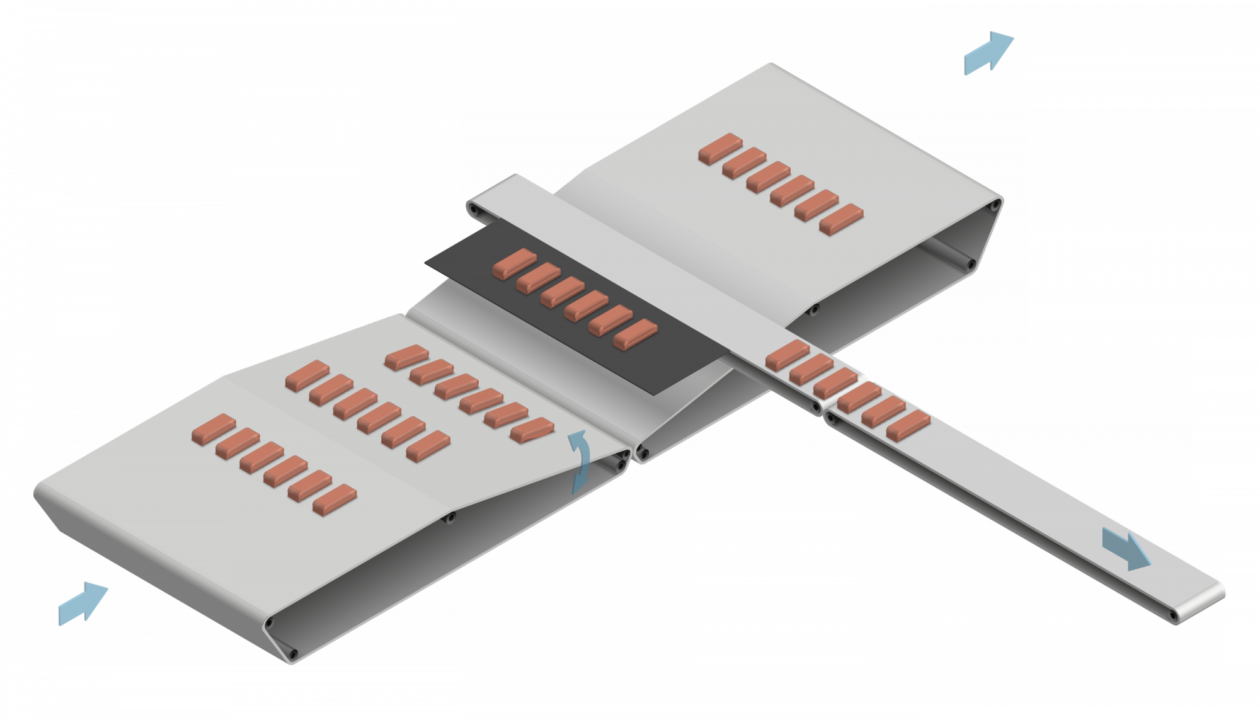

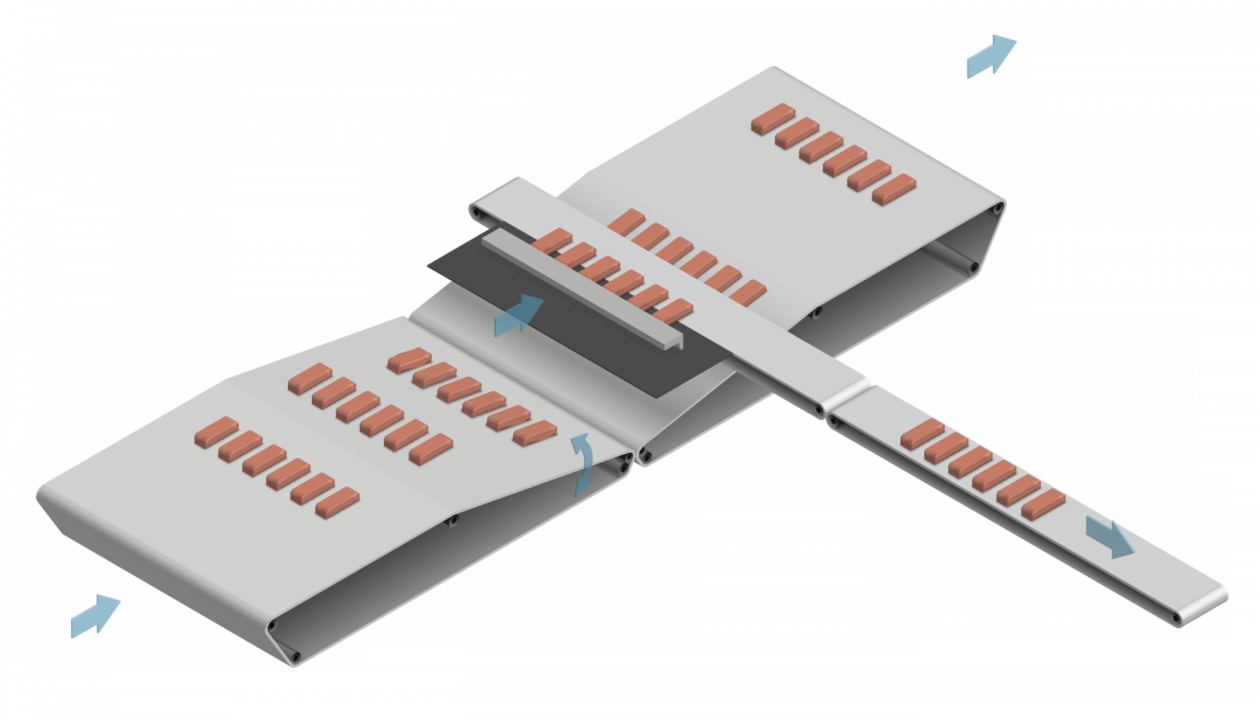

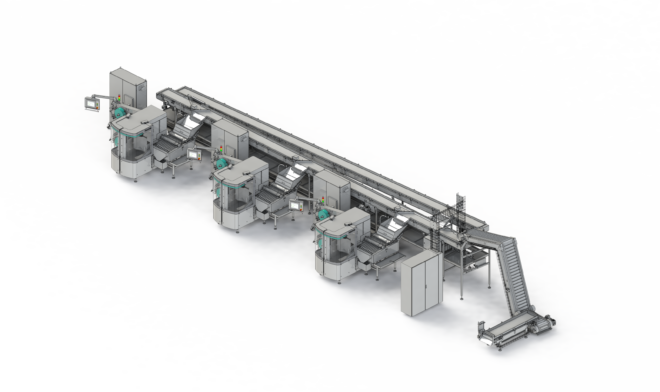

- To transfer the product rows via an oscillating nose conveyor to a cross transfer conveyor respectively to the next transfer station in direction of the flow

- Transfer of products from the oscillating nose conveyor to a dead plate

- Transfer of products from the dead plate to the cross transfer conveyor by a pusher

- Three-phase motor driven conveyor, frequency controller integrated within the switch cabinet

- Servo-driven tilting function and pusher

- Pneumatic web tracking control

- Easy access for cleaning through removable conveyor support plates

- Quick tensioning devices for the conveyor belts for easy maintenance and service

- All product transfers and scrapers with underneath sliding waste trays

- Return shafts with diameter 10 mm for smooth product transfer

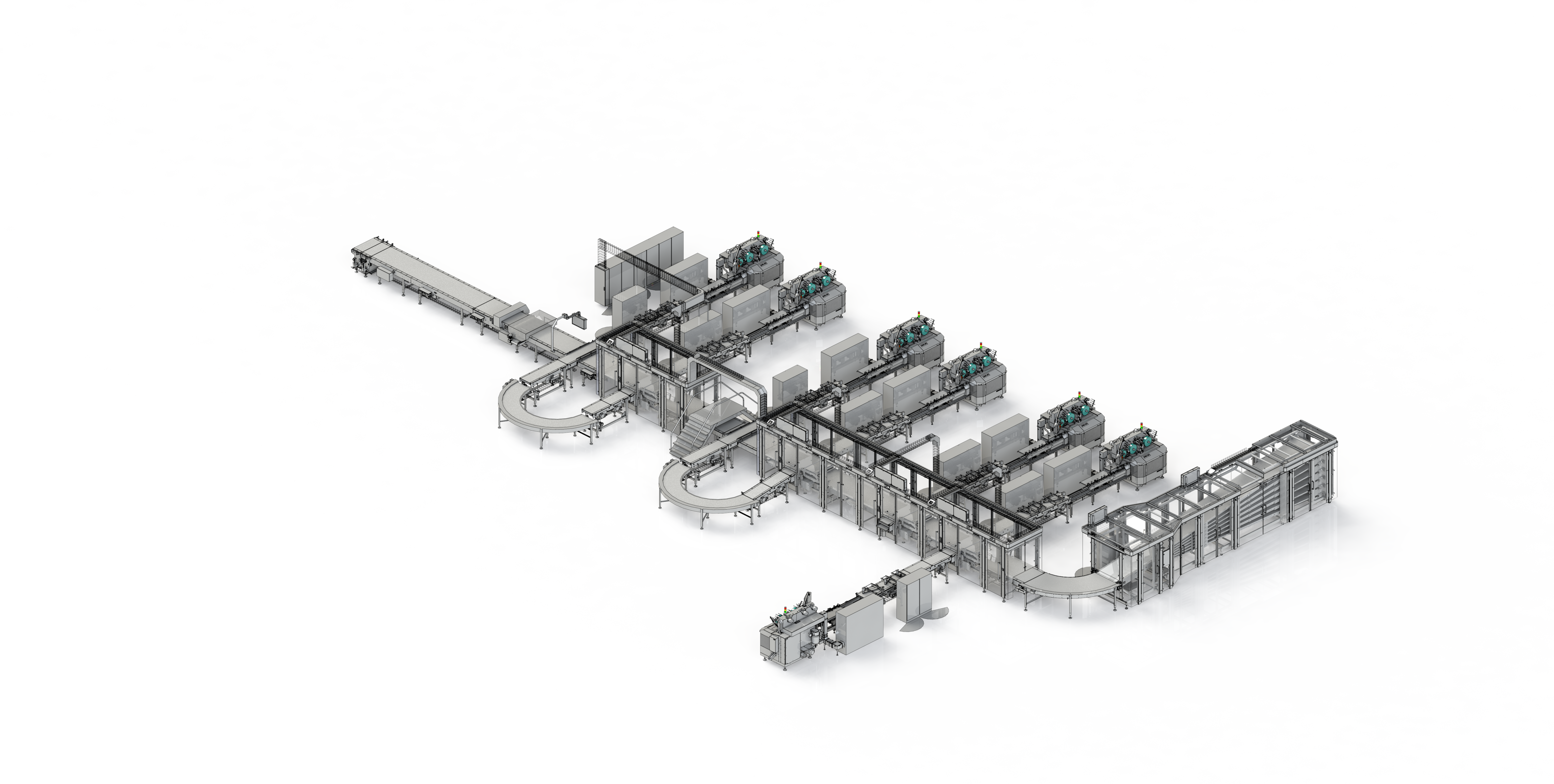

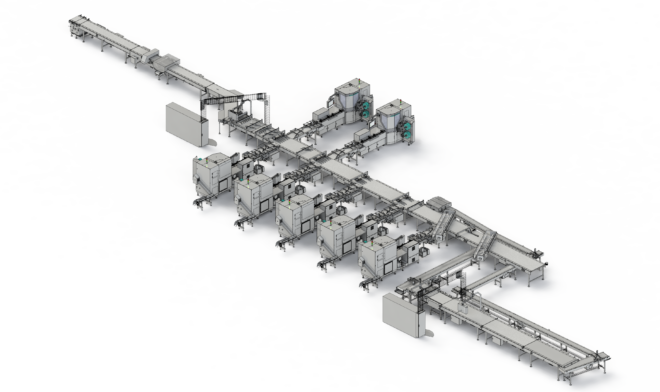

Cross Transfer Station with Pusher

Transfer of product rows from the main conveyor of the packaging system to the individual feeding sections of the different packaging machines.