© Theegarten-Pactec GmbH & Co. KG

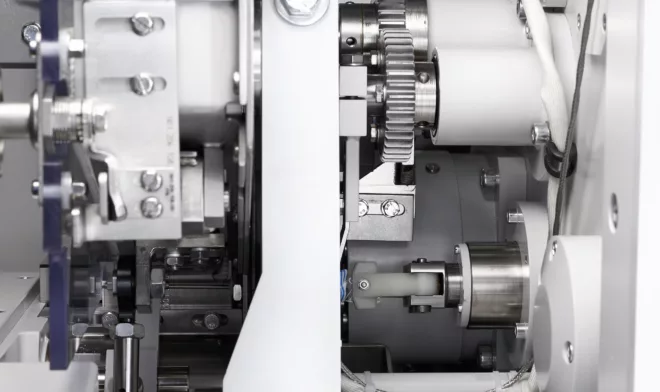

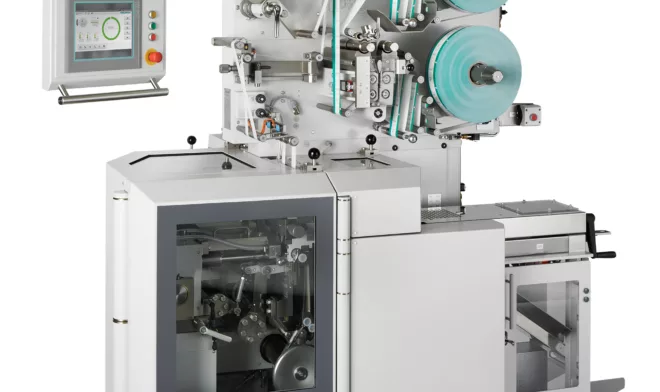

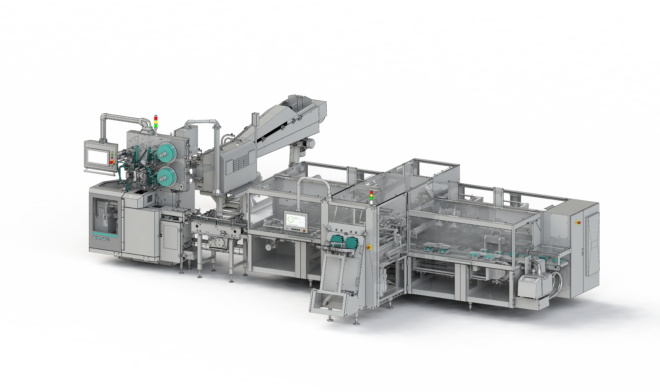

EW5 Schneid- und Verpackungsmaschine

© Theegarten-Pactec GmbH & Co. KG

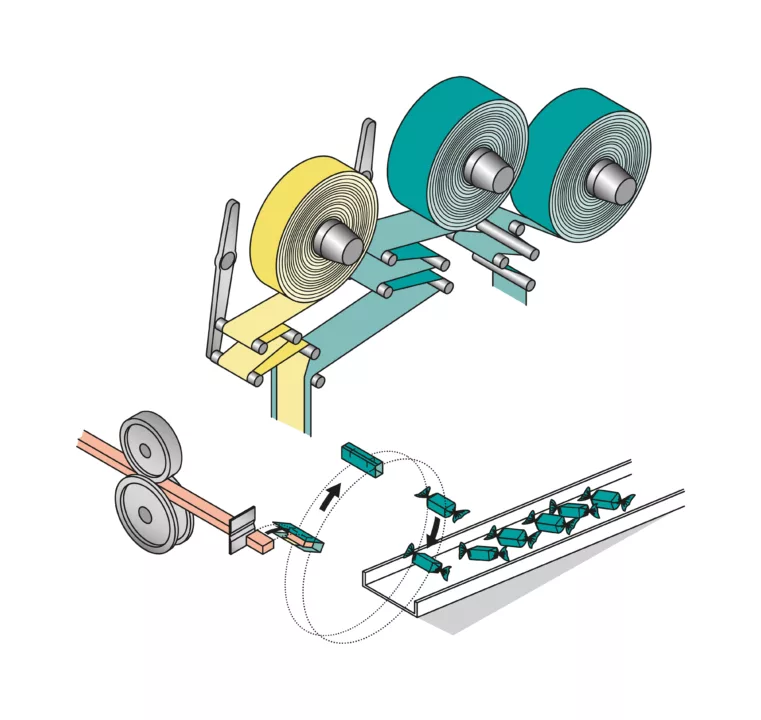

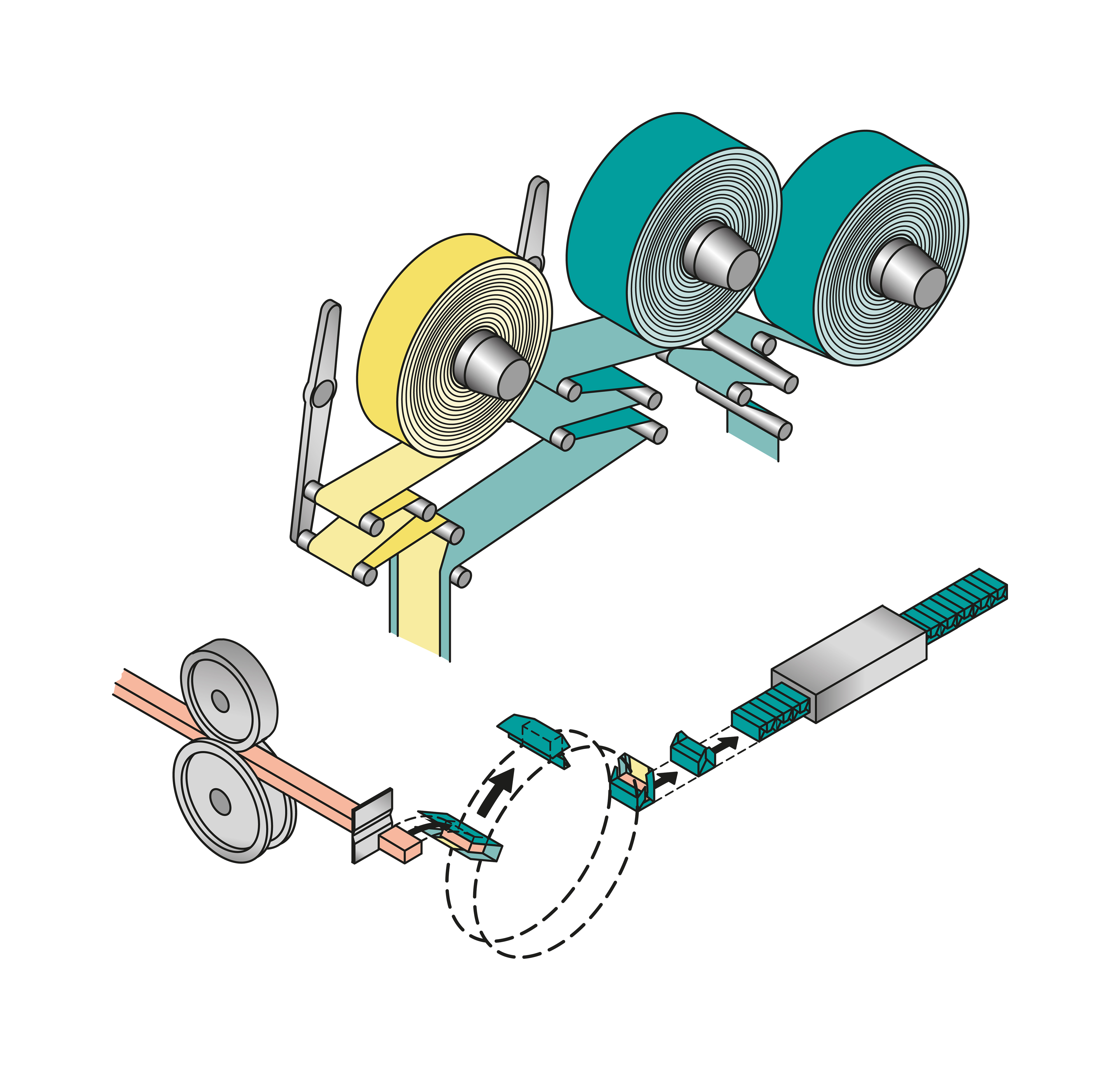

Verpackungsablauf Doppeldreheinschlag

© Theegarten-Pactec GmbH & Co. KG

Verpackungsablauf Bodenfaltung

© Theegarten-Pactec GmbH & Co. KG

600 verpackte Produkte / Minute in Doppeldreheinschlag

Verpackungssystem für Weichkaramellen

Aus der Kombination unserer zuverlässigen Verpackungsmaschinen mit verschiedenen Zuführ- und Speicherkomponenten entstehen komplexe Systemlösungen für das Erstverpacken – individuell gestaltbar.

Warum Theegarten-Pactec?

Wie wurde Theegarten‑Pactec, was es ist?

Die Geschichte unseres Erfolgs ist keine Kurzgeschichte. Seit über 80 Jahren stehen wir für unternehmerischen Mut und wegweisende Weitsicht. Entdecken Sie selbst, wie persönliche Handschrift und eigene Leistung unser Unternehmen zu dem gemacht haben, was es heute ist.

Dafür steht Theegarten-Pactec

Unser Erfolg ist kein Zufall. Mit einer gemeinsamen Vision, einer klaren Mission und starken Werten stehen wir an der Spitze der Branche.

Forschung und Entwicklung

Entdecken Sie die Welt der Verpackungstechnik bei Theegarten-Pactec. Als Spezialist für Verpackungsmaschinen und -anlagen bieten wir innovative Technologien und höchste Präzision.

Nachhaltigkeit bei Theegarten‑Pactec

Wir sind uns unserer besonderen Verantwortung als Unternehmen gegenüber nachfolgenden Generationen bewusst und handeln entsprechend. Erfahren Sie hier, was uns in den Bereichen Soziales, Ökologie und Governance so nachhaltig macht.